automatic insulating glass process line gas filled

Key words:

Product Classification:

Product Details

1. insulating glass process line 7 sections Can make triple glass, double glass and step glass

II: WASH AND DRY MACHINE(STAINLESS STEEL )

A:Wash and dry machine(front )

B. Wash and dry machine(back )

It is also stainless steel for the back door, there is ladders back of whole line for checking machine

C: Seven motors installed on top of wash machine, six brushes installed six motors , and the left motor for transfering .

E: Low noise blower and installed heating on it to make hot air .

The blow work and stop automatic to cooperate with the line needed. because our line can wash and dry glass in advance when the machine is pressing ,it can store 3 pieces of glass for press needed, this way machine work faster and same time if wash machine no wash to wash the blower stop working to save power and continue to work automatic ,this way save electricity .

H. all the motors install on this machine earth connection, for example water tank motor earth connection, auto water filling system, fill water auto if needed .

I: water tank stainless steel, water can be heated, equipped with thick stainless steel drainage pipe and automatic overflow function.

J: one brush one motor, glass wash machine have seven motors installed

I. inside wash machine both stainless steel and bottom is double layer .

K. the brushes and other relevant parts not install directly bottom of the wash machine ,but there is one layer more for installation .

This avoid machine frame change after long time running

L.Three pairs brushes and can do low E glass.

M.Can wash different thickness of glass automatic.

Water spray by nozzle ,not only make hole in the pipe, this nozzle is easy to take out and change the water spay direction , the nozzle is universal.

N.glass dryer part both is stainless steel and the airknife is stainless steel.

II: Press machine liner bearing

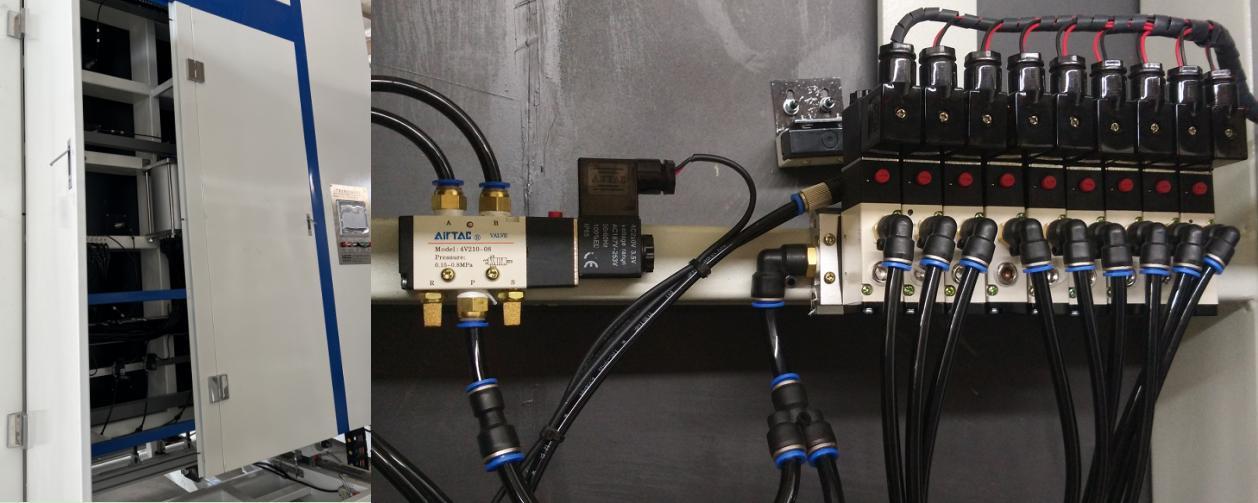

A. The press part cover make as door , it can be open easily for checking Press machine inside parts ( all the Electromagnetic valve and pneumatic parts is AirTAC famous brand from TAIWAN .

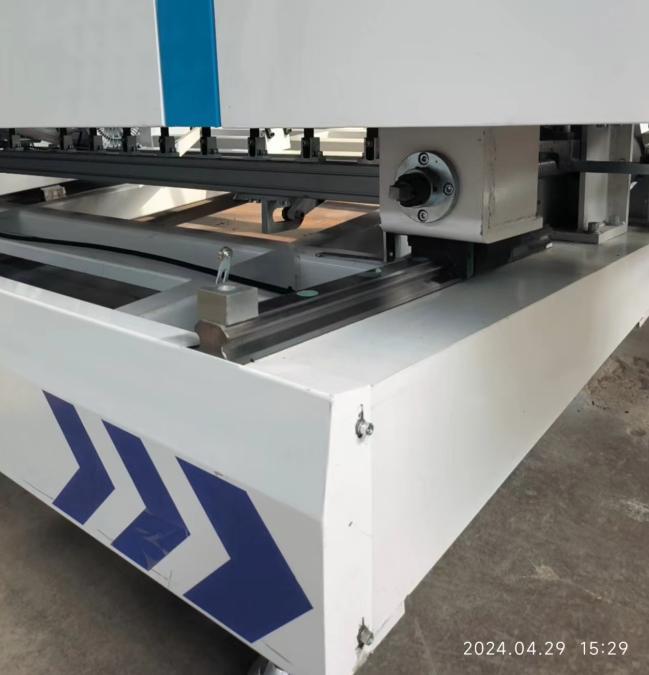

B.The downside black rollers with handle , use it to up or down the lifting parts for different size aluminum spacer , there is numbers for exact calculation, for the aluminum spacer bar position up or down .

D.Electrical cable

F:All the electric part schneider

J: press machine open and close realize by linear bear , others parts move also realize by linear bear

K: No trace design , so there will be no trace in the middle of the insulating glass

Parameter:

Voltage:380V50HZ

Power: 30 KW

Max.size of original glass: 2500*3600mm

Min.size of original glass: 400*400mm

Thickness of original glass: 3-19 mm

Thickness of insulating glass: 55mm

Work speed: 0-45 m/min

Wash glass speed :0-12m/min

Technical parameter

|

Parameter |

LB2025 |

LB2030 |

LB2536 |

|

Power Supply |

380v 50Hz |

380v 50Hz |

380v 50Hz |

|

power |

30kw |

30kw |

34.0kw |

|

Max size |

2000×2500mm |

2000×3000mm |

2500×3600mm |

|

Min size |

300×500mm |

300×500mm |

300×500mm |

|

Glass thickness |

3—12mm |

3—12mm |

3—12mm |

|

Transport speed |

8—45m/min |

8—45m/min |

8—45m/min |

|

Weight |

5500kg |

6000kg |

7000kg |

|

Overall dimension |

19000×1800×3100mm |

22000×1800×3100mm |

26000×1800×3600mm |

Related Product recommend

ONLINE MESSAGE

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Contact Us

Please contact us in the correct way and we will provide you with detailed information.

Dangjiazhuang industry area, Jinan city ,Shandong province ,China

WeChat Sweep